Determine 1: The Workforce. From left to proper: Serena Cicin-Sain, Olivia Organ, Will Foster, Joseph Moore, and Sherif Sawwaf. Not current within the image: Harry Armstrong, Oluwaseun Adewola,and Josh Orme-Herbert

“This undertaking has confirmed to be immensely priceless because it allowed us to comprehensively navigate a whole undertaking lifecycle, partaking in all sides, together with analysis, design, integration, and undertaking administration, all whereas adhering to a Methods Engineering strategy. The endeavor offered vital challenges, necessitating the group to proactively show initiative by way of in depth analysis and progressive problem-solving. A group member capitalized on this expertise to show their abilities to potential employers, securing a job in an engineering position. The undertaking, marked by its challenges, has additionally been pleasurable and rewarding, notably given the constructive suggestions we’ve obtained. Our group takes appreciable delight in our collective accomplishments, recognizing that it was our unwavering dedication and seamless teamwork that made all of it potential. We lengthen our honest gratitude to our supervisor, Payam Soulatiantork, and Roberto Valenti from MathWorks, each of whose invaluable information and steerage have been indispensable to the undertaking’s success”.

Introduction

The chosen problem undertaking required the group to design, mannequin, and simulate an autonomous quadruped robotic geared up with a robotic manipulator to carry out refined decide and place duties. To successfully accomplish this problem the group organized itself into 4 sub-teams, every engaged on one of many 4 subsystems: quadruped, manipulator, navigation, and notion. Work performed on every subsystem by a particular group was built-in right into a single autonomous robotic system through which a high-level state machine instructions every job of the robotic whereas protecting monitor of the system state. In the course of the undertaking improvement section, efforts have been coordinated and supervised to make sure well timed completion whereas prioritizing duties and member duties to fulfill the predefined necessities. Threat assessments have been additionally factored in to mitigate potential challenges.

Quadruped modeling and simulation

The quadruped sub-team designed a robotic replicating animal gaits, specializing in a diagonal superior placement akin to canine and horses. Their design featured 4 legs with three hyperlinks and joints, making certain coordinated motion inside a one-cubic-meter quantity. This design allowed environment friendly locomotion and stability, together with a steady stationary gait. The group’s inspiration from animal locomotion ideas enabled efficient motion of the robotic and led to profitable implementation. The group started with a

As soon as the quadruped efficiently achieved turning actions whereas sustaining stability, the group carried out a high-level Stateflow job planner for enhanced navigation. This job planner determines the quadruped’s motion mode (stationary, strolling straight, turning left, or turning proper) based mostly on the relative angle and distance to the goal coordinates, enabling efficient navigation and impediment avoidance. An illustration of the quadruped locomotion together with a visible of the strolling controller and the high-level job planner is proven in Determine 2.

The profitable implementation of a steady strolling and turning management algorithm, was a crucial achievement for the quadruped undertaking and served as a basis for integrating the opposite subsystems.

Determine 2: Quadruped strolling gait demonstration. (High) Excessive-Stage Stateflow diagram for movement mode transition and execution, (Backside Left) Stateflow stroll cycle for the Raibert technique mode, (Backside Proper) Quadruped 3D visualization.

Manipulation

Determine 3: The top effector. (Left) Simscape mannequin, (Proper) full manipulator with connected the tip effector.

To allow object interplay, an finish effector with three fingers was connected to the manipulator. The top effector has two revolute joints per finger, as proven in Determine 2, permitting it to imitate human fingers and securely grasp objects. Inverse kinematics calculations have been carried out utilizing a inflexible physique tree and ahead kinematics fashions. A ahead kinematics mannequin was generated to find out the place and rotation of the tip effector based mostly on the joint angles. An inverse kinematics solver using the Broyden-Fletcher-Goldfarb-Shanno (BFGS) Gradient Projection algorithm was carried out to search out the joint angles required to achieve a given remodel.

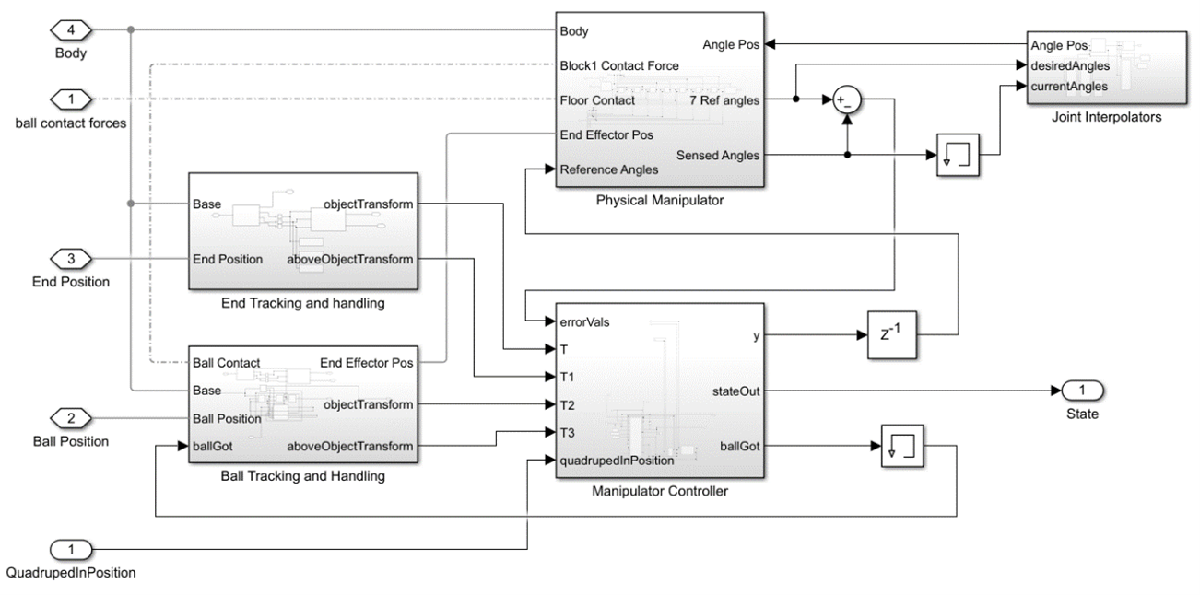

A high-level controller facilitates object selecting throughout the outlined setting. The manipulator subsystem (Determine 4) features a state variable for communication between the quadruped and manipulator. This variable determines when the quadruped is positioned subsequent to the article or the specified finish place.

The manipulator job planner manages the order of operations and ensures that the manipulator reaches the right place earlier than continuing. It coordinates the actions of the manipulator joints and displays the states of all subsystems.

Determine 4: The total manipulation subsystem mannequin.

With the manipulator subsystem carried out, the manipulator is ready to decide up objects throughout the setting. The top effector, geared up with three fingers, curls round an object to safe it in place. Contact forces between the ground, object, and manipulator have been simulated for practical interactions. An entire decide and place job of the manipulator subsystem is proven in Determine 5. The manipulator subsystem was built-in with the quadruped, permitting communication between them.

Determine 5: A ball selecting demonstration.

Navigation

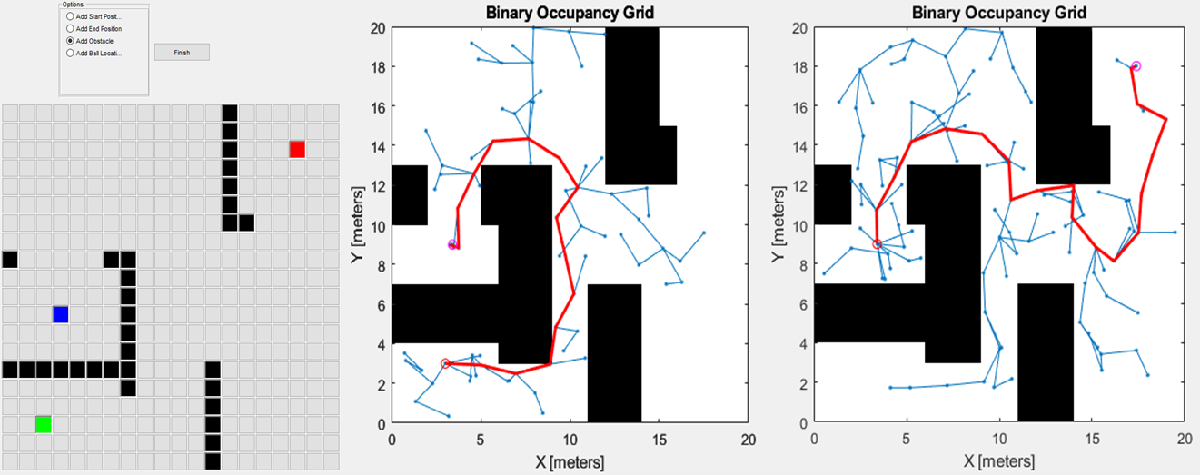

The navigation sub-team adopted the RRT* algorithm for path planning, enabling the quadruped to navigate by way of user-defined environments. The RRT* algorithm optimized paths for effectivity, combining two deliberate paths, particularly begin to pick-up and pick-up to drop-off, into one array as proven Determine 6.

Determine 6: (left): Useful GUI with begin, decide up and place places, and impediment blocks, (center): occupancy grid path from begin to object pick-up place, (proper): occupancy grid path from pick-up to finish place.

Controller optimizations included changing PID controllers with 1-D lookup tables for manipulator joints, making certain smoother manipulative actions, and implementing a feedback-based braking system to repair the ball securely to the manipulator’s palm. The high-level management logic was managed by the duty planner carried out in Stateflow, which orchestrates duties corresponding to path following, ball pick-up, placement, and simulation termination.

Determine 7: An illustration of a consumer interplay with the GUI: Creating an setting map, putting objects, and triggering automated technology of a 3D situation and navigation path.

Integration

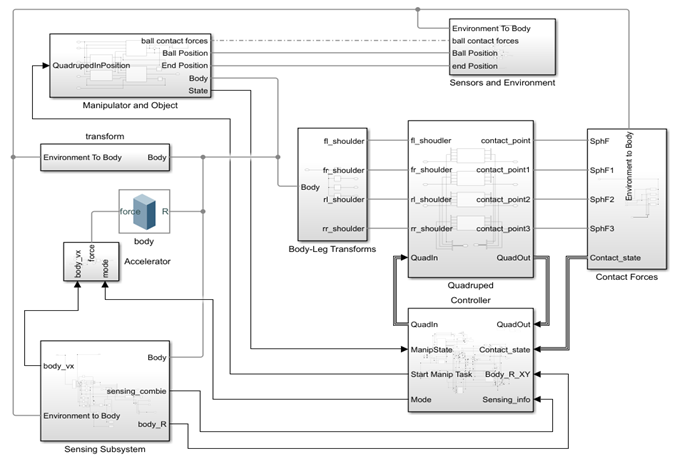

Within the closing levels of the undertaking, the group achieved seamless integration of varied subsystems to create a functioning autonomous robotic system. The Simulink mannequin illustrating this integration is offered in Determine 8. The GUI performed a pivotal position in producing intricate maps and setting waypoints. The Path Planning subsystem, coupled with a Goal Selector, allows the quadruped to navigate exactly, making certain it follows the designated path precisely.

The Path Follower Stateflow module makes real-time selections based mostly on inputs from the Goal Selector and the Angle and Distance Finder. It orchestrates intricate actions, together with turns, halts, and ahead strides, making certain the quadruped’s adherence to the predefined route.

On the core of this integration, the Job Controller Stateflow oversees your entire course of. It displays the place index, making certain the quadruped reaches every waypoint as deliberate. Moreover, it manages the initiation of complicated duties like selecting up and dropping off the ball, synchronizing these actions seamlessly throughout the total motion plan.

The Quadruped Motion Controller performs a vital position in executing exact joint actions. These actions are meticulously calculated to take care of stability and stability, making certain the quadruped’s actions are each correct and safe.

The strategic placement of the manipulator on the quadruped’s allows a stability between stability and performance, permitting the manipulator to carry out duties effectively with out compromising the quadruped’s stability throughout locomotion.

This detailed integration course of highlights the group’s technical experience, showcasing their learnings in system integration that turns subsystem parts right into a unified and operational robotic system. Determine 9 reveals a simulation of the ultimate built-in mannequin of the complete system in motion.

Determine 8: The total system Simulink mannequin

Determine 9: The total system in motion.

Conclusion

Engaged on this Problem Downside supplied the group with a possibility to be taught a number of real-world abilities. They discovered the way to break down a big complicated robotics drawback into smaller subsystems, design and implement these subsystems, and combine them into an total functioning system. All through this strategy, modeling and simulation enabled them to design their performance in such a approach that met the high-level necessities.